The Civil War is many times referred to as the first "modern"

war, one in which the armies were broken into specialized arms. General

Henry H. Hunt, a West Point graduate and career artillery officer, had advocated

that Artillery should be a separate arm, like Cavalry, for many years prior

to the war. In 1858, he was one of three officers chosen to rewrite the

Field Artillery Manual, and defined that the service of batteries assigned

to brigades of Infantry or Cavalry was subordinate to the operation of the

unit, but that the Artillery Reserve was a distinct arm of battle, commanded

by it's superior officer, under the immediate orders of the general commanding.

There were two distinct types of artillery units; Heavy (or Foot) Artillery,

and Light (or Field) Artillery. Heavy Artillery units were responsible for

seacoast, garrison and mountain artillery. During the war, there were so

many extra regiments of Heavy Artillery that many of them were issued muskets

instead of cannon, and served as infantry.

Light or Field Artillery is divided into two parts; Horse Artillery, where

all the men rode horses and served with the Cavalry, and Mounted, where

the men marched alongside the cannons. When the Mounted units went into

battle,the men jumped onto the cannon and limber and rode into the action.

The makeup of the army changed during the early years of the war, but after

1863, the usual makeup of an army corps was three divisions of infantry

and one brigade of artillery, consisting of five batteries of six guns each.

Late in the war it was not unusual for batteries to be reduced to four guns, due

to shortage of available horses (the government paid $160 for a Cavlary horse, but $170 for

an Artillery horse).

The remainder of the Field and Horse Artillery made up the Artillery Reserve,

even though it was hard for many in the army not to think of it as a place

to get replacements.

At Gettysburg, General George Meade originally thought he only had the guns

attached to the corps, and questioned Hunt about having enough guns or ammunition

for the fight. The battle showed the Artillery Reserve's strength, as there

were 21 batteries mounting 118 guns of the Union total of around 360 guns.

On the second day, when the Third Corps was broken at the Wheat Field and

the Peach Orchard, it was the Artillery Reserve which stemmed the Confederates

and held the line. Colonel Freeman McGilvery had the First Volunteer Brigade

of the Artillery Reserve, which consisted of the 5th and 9th Mass, the 15th

New York and Battery C/F, Penn Light Artillery, in support. As the infantry

was broken the artillery held its ground to cover the withdrawal. Under

pressure of the Confederates, lead by General William Barksdale's Mississippians,

one battery had withdrawn, out of ammunition, and the other three had been

forced back to the Trostle Farm, when McGilvery noticed that the remains

of the Third Corps had not reformed at the crest of Cemetery Ridge, as he

had anticipated. He gave the 9th Mass commander, Captain John Bigelow, the

task of holding off the Confederates while he rounded up what artillery

he could, to form a new line. The 9th lost four of it's guns, and Bigelow

was seriously wounded, but it gave McGilvery time to put about 15 guns along

what was referred to as the Plum Run line, and held until General Winfield

Hancock arrived with the Third Brigade of the Third Division of his Corps,

which drove back the Confederates, mortally wounding Barksdale, and holding

the line.

Four 20 pound Parrott Rifles, 1st NY, Peninsula Campaign, June, 1862

A standard Field Artillery battery consisted, at full strength, of six guns. Each gun was attached to a limber pulled by six horses, and was supported by a caisson, also attached to a limber pulled by six horses. The caisson carried two ammunition chests (also a spare wheel), and there was one chest on each limber for a total of about 1,200 rounds for the battery. There was also a battery wagon, a forge wagon and an ambulance, for a total of 18 vehicles.

There were drivers on the left side horses, each responsible for two horses. When horses were in short supply, (a battery needed about 125) mules could be used, though they tended to shy in battles, so horses were used for the guns (leading to four gun batteries in part of 1864 and again in 1865). Exposed in battle, killing the horses of a battery prevented moving the guns from the field when threatened by the enemy. This proved to be a problem for the Ninth Mass Battery at Gettysburg (July, 1863), and for the Tenth Mass Battery at Ream's Station (August, 1864). The Tenth Mass Battery went through about 400 horses (battle casualties, exhaustion and disease) during the course of the war, and when turning in their horses at the end of the war, had only one of the original 110 they had left Massachusetts with.

caisson and it's limber

A battery had five officers; one captain commanding, one lieutenant in charge

of the caissons, and one lieutenant in charge of each of the three sections.

A section consisted of two guns and their crews, and were referred to as

"left", "center" and "right", even though

in a battle, the "left" section might be deployed to the right

of the "right" section.

A detachment was one gun and its crew. The Chief of the piece was a sergeant,

in charge of the gun; there was a corporal in charge of the caisson, and

another who was the gunner that aimed the piece. The "spare men"

of the Battery were those who were unassigned, and took care of the horses

and equipment. Those who were assigned to the "numbered positions"

had a bit of status within the Battery, at least in terms of their own pride.

The cannoneers were: #1, who swabbed the bore and rammed the load; #2, inserted

the charge and projectile into the muzzle; #3, tended the vent; #4 primed

and fired the piece at the command of the sergeant; #5, carried the round

to #2; #6 had charge of the limber; and #7 carried the round to #5.

When in action, the gun would be driven into position, the gun would be

removed from the limber by the cannoneers and brought to bear on the target. If need be, the

#1 man would use the 'worm' to remove any material from the bore and swab

it with a damp sponge rammer. The gunner would decide the range, and tell

#6 at the limber, along with the type of round required. Then the gunner

would mount the sight, and begin to aim the gun. #6 would prepare the round,

using the Firing Table in the Limber Box to choose fuse time. #7 would carry the round

to the #5 man who delivered it to the #2 man standing by the muzzle of the

gun. He would position it in the muzzle of the gun for the #1 man to ram

down the bore. All this time, the #3 man has covered the vent to keep air

from any embers that may be present. When the round is seated, the #3 man

would use a pick (the priming wire) to pierce the powder bag. #1 and 2 at the wheels of the gun

and #3 at the trail spike would assist the gunner by moving the gun left or right.

After the gunner is satisfied with his job, he removes the rear sight and

steps back from the gun. The #4 man inserts a primer into the vent, attached to

the lanyard, and steps back, #3 helping keeping the lanyard taut.

At this time, with the cannoneers

safely away from the gun, it is ready to fire. Upon command of the Chief

of the piece, #4 pulls the lanyard firing the cannon. #1,2 and 3 move it

back into battery (correct position), and the cycle starts again.

At the beginning of the war, the guns in service were a mix of 6- and

12-pound smoothbores left over from the Mexican War, and the new rifled

pieces. The smoothbores were best used against troops, especially up close;

while the accuracy and power of the rifled guns had made even the strongest

fortress vulnerable.

In addition, there were a number of types bought in limited numbers to fill

shortages in the field making the logistics quite difficult. As the war

went on, it was determined that for concentrated firepower, and ease of

supply, Light Artillery Batteries should be homogeneous. The non-standard

guns were relegated to training or the Western theatre, and in some cases,

6-pound guns were melted down to make 12-pounders. At Gettysburg, of 61

batteries, only two were mixed. The Ordnance Board decided to change the

bore of Parrotts from 2.9-inch to 3-inch, standardizing two calibres in

the field - the 3-inch rifle and the 12-pound smoothbore.

The Confederates fielded what they could manage. Since much of their

artillery consisted of captured Union guns, they made do as best they could. At Gettysburg the

Louisiana Guard Artillery was issued 3-inch ammunition for

their 2.9-inch guns, temporarily disabling three guns.

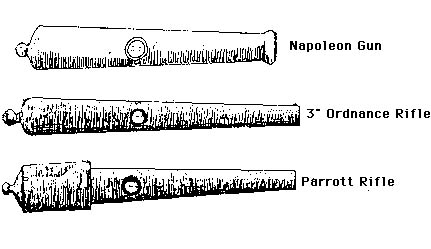

The major categories were:

-12-pound smoothbore, with either 6 Napoleon (Light Gun Howitzer Model 1857)

or four Napoleons and two Model 1841 Howitzers - most useful against troops

at a range of one mile or less, they threw a large shell (4.62 inches) and

a deadly canister round (48 one inch balls for the Howitzer, 27 from the

Napoleon) [A howitzer is meant to fire in a higher trajectory than a gun,

has a chamber at the breech, and is lighter than a gun of the same bore].

-3-inch Ordnance Rifle, used to attack the enemy's batteries from over a

mile away, with a maximum range of 4,000 yards .

-10-pound Parrott Rifles, used as the Ordnance Rifles.

3-inch Wrought Iron Rifle

The gun was produced by the Phoenix Iron Works of Phoenixville, Pennsylvania, with a few design changes wanted by the Board (it was also discovered at this time that the bands usually found on cannon of the times actually produced stress points, so the contour of the gun is very smooth). Samuel Reeves of Phoenix made improvements to the forging and welding process and was awarded a new patent in 1862 (which caused a split between Reeves and Griffen for many years). This cannon has been referred to as the 3-inch Ordnance Rifle and the 3-inch Wrought Iron Rifle, and erroneously as a "Rodman". [Captain T.J. Rodman, was on the Ordnance Board, but his specialty was cast iron guns. As head of the Watertown (MA) Arsenal, he perfected a way to pour cast iron into a mould that rotated, making a strong gun, and this process was used to make larger guns. There is no record of him having any influence on the 3-inch Wrought iron rifle, though it may be argued that the rimbases were consistant with a cast gun instead of a machined one.] Around 1000 3-inch Ordnance Rifles were bought during the war. (The Ordnance Board also developed a 4.5-inch Siege gun, with lines very similar to the 3-inch gun, but made of cast iron.) |

Parrott Rifle

Robert P. Parrott, at the West Point Foundry, came up with a new method for strengthening a cast iron gun with a band of wrought iron at the breech. The design of reinforcing bands was, in itself, not new; many Confederate guns were cast iron with bands for added strength, and they also banded and rifled many captured Union smoothbores. Parrott's method was to form a band of iron around a mandrel, hammering it until it was welded into one piece, then while hot forcing it onto the breach of the tube being water cooled on the inside. Parrott rifles were made in 10- and 20-pound field pieces, 30-pound siege guns and 100-, 200- and 300-pound seacoast and Navy guns. This design was cheaper and easier to produce, but tended to burst right in front of the reinforce (a 200-pound gun at Morris Island, South Carolina burst after just 36 rounds). The original 10-pounder (Model 1861, characterized by a muzzle swell) had a bore of 2.9-inches, while the Model 1863 (no muzzle swell) had a bore of 3-inches in order to standardize the ammunition. In February, 1864 Second Model Parrotts were accepted (of approximately 279) by the Board; in June the First Models were pulled out of the field, and many were rebored to 3-inch(119 out of approximately 250 First Models made). It does not seem any of these were re-issued, as none survive today. Approximately 600 (total of both models) 10-pound Parrotts were purchased during the war (additionally, some were purchased by states). When is a Parrott not a Parrott? Mmany times a banded cannon is thought a "Parrott". However, the Confederacy made banded Napoleons, Brook banded Rifles and banded some large smoothbore heavy artillery guns fro added strength.; the Union had Delafield 3.67" Rifles. |

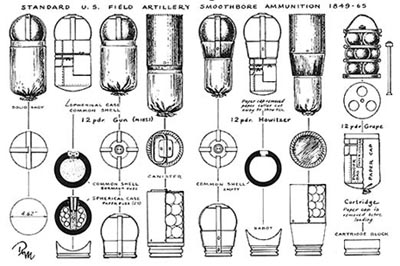

Here is an explaination of cannon ammunition typically used in the Civil War. For a in-depth look at Artillery Munitions, see Jack Melton's web page. He and Lawrence Pawl have produced a wonderful book showing the varieties of ordnance, Introduction to Field Artillery Ordnance 1861-1865, by Jack W. Melton and Lawrence E. Pawl, Kennesaw Mountain Press. |

Both smoothbore and rifled guns could shoot the same type of ammunition;

solid, shell, case and canister (or grape).Solid shot (a bolt if from a

rifled gun) was used to batter fortifications, against wagons, buildings,

or troops. In the latter use, the smoothbore was superior because the ball

could be skipped across a battlefield, inflicting casualties over a large

area of the field. At Gettysburg, an officer is said to have observed a

ball bouncing along far in the rear, and stuck his foot out to stop it,

having his foot removed for his troubles. Shell were hollow projectiles

filled with gunpowder, and exploded by a fuse. Case shot was a hollow projectile

with thinner walls than the common shell, having a bursting charge and filled

with smaller balls (the Union usually used lead balls, the south iron; in

a pinch minie balls were used). This was exploded by a timed fuse while

still in the air so that all the shot inside and pieces of the shell dispersed

and flew to the target. Canister was a cylinder filled with balls packed

in sawdust; when the gun was fired, the cylinder disintegrated and the balls

fanned out as if from a giant shotgun.The 12-pound Napoleon had a charge

of 27 one and a half inch iron balls; 12-pound howitzer had 48. The last

rallying cry of a battery under siege was "Double canister at ten yards!".

Rifled guns could shoot canister, but it was said that the rifling gave

a twist to the shot which made it spread in an erratic spiral. Later designs

of rifled cannister had a rigid iron container for the balls which would

not spread into the rifling to try and keep the pattern form spiraling.

There was also a design which had a charge in the canister which went off

after the round left the tube, adding to the range of the balls. Grape was

9 larger balls, held together by iron plates, or covered in canvas and tied

with heavy twine (quilted grape).

Spherical shot for smoothbores were attached to a wooden sabot. The powder

bag could be tied to a groove in the sabot so the round could be loaded

in one piece, and this arrangement also kept the fuses of exploding shells

pointed toward the muzzle (if the fuse was pointed down, it could be driven

into the fuse hole and explode the shell as the propellant charge was fired).

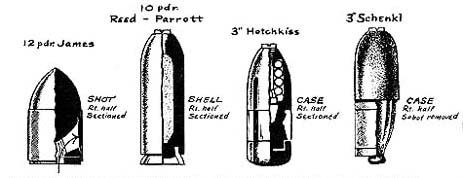

Rifled cannon needed the projectile to engage the rifling to be accurate, but it must be small enough to load from the muzzle on the battlefield. This was accomplished in different ways, which fall into three major categories: expansion - where a ring or cup of soft metal (lead, copper) expanded at the base of the round by the gases at firing; forcing cone - where the rear of the projectile (paper-mache, lead ring -iron cup) was forced toward the front, expanding a band of soft metal into the rifling; and shaped - where the projectile was the same shape but a smaller diameter, and had ridges or flanges which fit into the rifling.

In September 1864 the Ordnance Board ordered that Parrott projectiles

be used exclusivley in Parrott guns, and Hotchkiss projectiles when Parrott

were exhausted; Shenkl projectiles were forbidden from Parrott guns; and

Parrott projectiles were forbidden from 3-inch Ordnance Rifles.

Primers and Fuses

When the gun was loaded, and ready to be fired, the #4 man of the gun crew

would insert a friction primer into the vent, attach the hook of the lanyard

to the loop of the primer, back away the 12 feet that the length of the

cord was and wait for the command to fire given by the gunner. Primers were

most often made of a long and a short copper tube, soldered together at

right angles. The longer tube was filled with gunpowder and sealed at the

bottom with wax, and went into the vent. On the top, the shorter tube was

filled with a friction mixture, and a twisted wire was inserted into it,

the end of which formed a loop. When the wire was pulled through the friction

mixture, the powder was ignited, shooting a flame down into the powder bag

firing the gun.

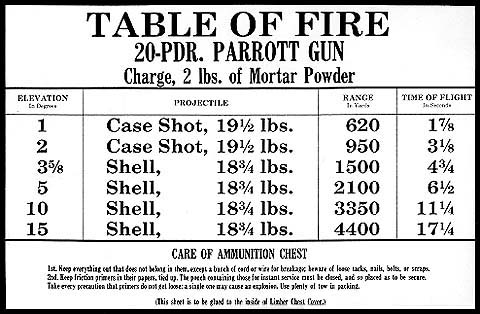

The most common type of time fuses were made of paper cylinders packed with

a slow burning powder. There were markings for shortening the burning time

marked on the fuses (there were also "fuse measures", a board

with a groove for the fuse to sit in, with more accurate graduations). When

the gunner established the range to the target, the #6 man would give him

the corresponding elevation to use (from the Table of Fire glued inside

the limber chest), and cut the fuse to the length required for the time

of flight. The fuse, cut to the correct length, would be inserted into wooden

or metallic fuse plugs in the fuse hole of the projectile. For consistency,

starting in late 1862, the Union had all paper time fuses manufactured at

the Frankford Arsenal. Confederate fuses had to be made at a variety of

establishments to supply the need, and therefore varied in consistency.

The Bormann time fuse was made of metal which screwed into the fuse hole

of the ordnance. A hole was punched into the top at a mark corresponding

to the length of time wanted. This was more convenient, but not more accurate,

and there are existing specimens of Borman time fuses which had been drilled

out so that a paper fuse could be used. In both cases, the fuse was ignited

by the flame of the propellant charge.

Rifled shells which were fitted with paper fuses sometimes did not have

the fuse ignited by the propellant charge. There are some designs of rifled

shell and case which had flame grooves up the side of the projectile so

that the flame could ignite the fuse before the band was flared into the

rifling. Projectiles could also be fitted with percussion or concussion

fuses, but these were not as reliable. Percussion fuses had a movable piece

with a cone, onto which a percussion cap was placed. When the shell hit,

the slider was thrown forward, detonating the cap against the anvil fixed

in the fuse. This design didn't work reliably if the slider got cocked,

or if the shell hit a glancing blow, not giving enough force to fire the

cap. Concussion fuses were designed to go off upon hitting at any angle,

but these were unpredictable and dangerous.

There were stories of troops being hit by shells fired by their own side

which burst prematurely, and that no doubt happened. Many times it was the

sabot, a piece of the rifling band or just a piece which broke off the shell

as the cannon fired which struck those troops. Many recovered Parrott projectiles

have pieces broken off at the base, attributed to the force of being fired.

For another look at Civil War Artillery, and other links on the subject, go to Chuck Ten Brink's Artillery page. Some of the images used here are his scans that he has allowed me to use.

interested in shooting artillery ??

see the American Artillery Association

the North-South Skirmish Association

Shooting Muzzleloading Artillery

Sleeper's Battery | 10th Mass Btty, N-SSA (and other links)

v.cw1-MMIII0620